Category: Animal

Categories

Bison Hair fibre

Categories

Angora Rabbit

Categories

Vicuna Fibre

Categories

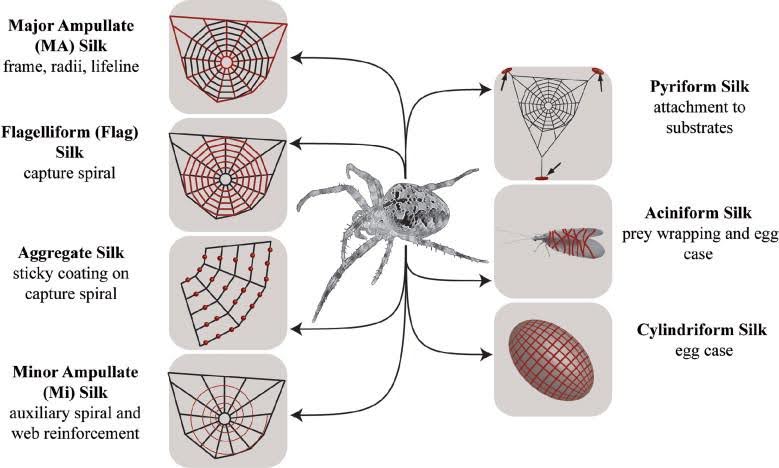

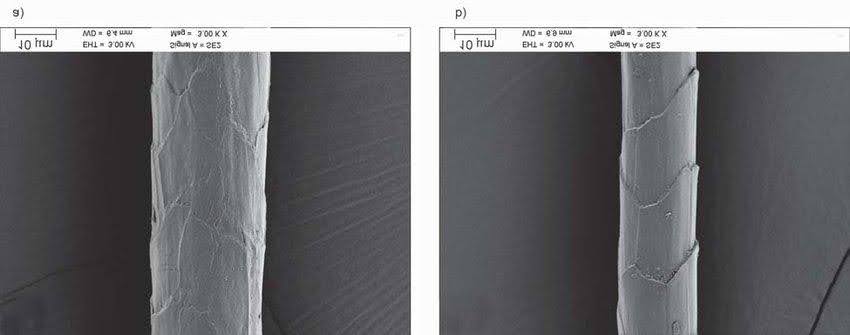

Spider Silk

Categories

Llama Fibre

Categories

Pashmina hair

Categories

Camel hair